เครื่องซีลสูญญากาศ เครื่องแพ็คสูญญากาศ / แพ็คถุง/ เครื่อซีลถุง ใช้การปิดถุงด้วยสุญญากาศ

-

-

- เครื่องแพ็คสุญญากาศ ช่วยในการคงความสดของอาหาร

-

-

-

- ยืดอายุการเก็บรักษาอาหารได้นานยิ่งขึ้น

-

-

-

- สามารถแพ็คสินค้าได้หลากหลาย เช่น เนื้อสด อาหารทะเล อาหารสำเร็จรูป ใบชา สมุนไพร ถั่ว ฯลฯ นอกจากนี้ยังสามารถแพ็คสินค้าที่เป็นอะไหล่ หรือ Hardware อื่นๆ ได้อีกด้วย

-

วัตถุประสงค์ในการใช้เครื่องแพ็คสูญญากาศ

-

-

- เพื่อการถนอมอาหาร เก็บรัษาอาหารไว้ได้นานขึ้น

-

-

-

- ป้องกันการเสียจากจุลินทรีย์ และแบคทีเรียที่ต้องการออกซิเจน

-

-

-

- สามารถขนส่งอาหารไปได้ตามสาขาต่างๆ ได้ง่าย และสะดวกมากขึ้น

-

-

-

- ป้องกันความชื้น และอากาศเข้าไปในอาหาร

-

เครื่องซีลสูญญากาศ แบบตั้งโต๊ะ

Vacuum Chamber Machine-Table Top Model

เครื่องซีลสูญญากาศ แบบตั้งพื้น รุ่นฝาเดียว

Vacuum Chamber Machine 1 Chamber

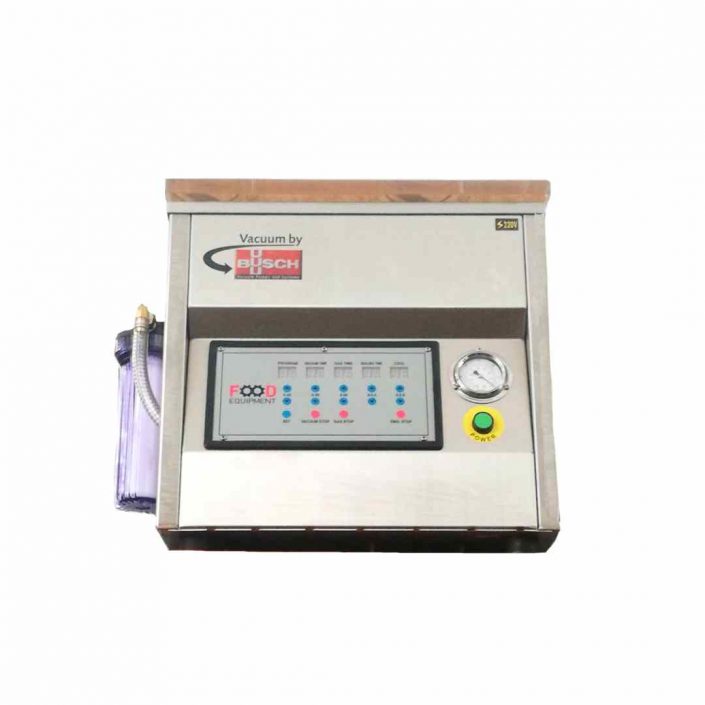

เครื่องแพ็คสูญญากาศ FOOD-612

ขนาดแถบซีล 400 มม., ปั๊มเยอรมัน Busch, มีชุดกรอง

เครื่องแพ็คสูญญากาศ FOOD-400

ขนาดแถบซีล 400 มม.

เครื่องแพ็คสูญญากาศ FOOD-500

ขนาดแถบซีล 500 มม.

เครื่องซีลสูญญากาศ FOOD-600

ขนาดแถบซีล 600 มม.

เครื่องซีลสูญญากาศ FOOD-623

ขนาดแถบซีล 800 มม., ปั๊มเยอรมัน Busch

เครื่องซีลสูญญากาศ JV-006

ขนาดแถบซีล 800 มม., ปั๊มเยอรมัน Busch

เครื่องซีลสูญญากาศ รุ่นอุตสาหกรรม

แบบตั้งพื้น รุ่นสองฝา ฝาโยก

Vacuum Chamber Machine 2 Chamber

บริษัท ฟู้ด อีควิปเม้นท์ จำกัด

630/8 ซ.บางแวก 64/1

แขวงบางแวก เขตภาษีเจริญ

กรุงเทพฯ 10160

Tel. : (02) 449-5999

Fax : (02) 449-5488

info@foodequipment.co.th

www.foodequipment.co.th

เวลาทำการ

จันทร์ - ศุกร์: 8.30 - 17.00 น.

เสาร์: 8.30 - 12.00 น.